AI Robotic Dogs Empower The Construction Of Airbus Fala-2 Project In Tianjin

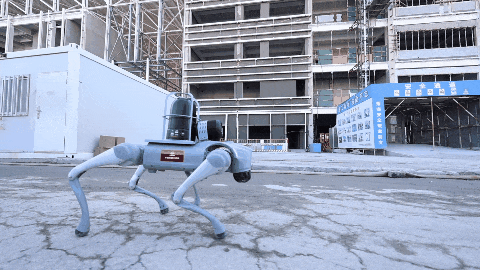

“Click-click-click...” At the construction site of the Airbus Tianjin Second Final Assembly Line Project, undertaken by China Railway Construction Bridge Engineering Bureau, the sound of mechanical braking periodically echoes. A gray robot dog deftly pauses and moves through the site, inspecting safety conditions and real-time transmitting patrol reports. This marks the first application of an AI inspection robot dog by China Railway Construction Bridge Engineering Bureau—a key measure to shift from "human control" to "machine control" through a digital management system, precisely overseeing construction progress and empowering project development with digital intelligence.

Top-Configured Helper

The "Smart Construction Site Sentinel" AI inspection robot dog is not only agile but also equipped with "sharp eyes" and "high intelligence," boasting powerful functions. Its "eyes" are infrared optical cameras and high-definition cameras, its "ears" are navigation lidar, its "mouth" combines obstacle avoidance sensors and an intercom, and its "brain" is an intelligent AI inspection system. Capable of hazard detection, intelligent patrols, and more, it autonomously returns to its charging station after completing tasks.

Expert Assistant

The robot dog’s "brain" is programmed for the project’s specific construction scenarios, analyzing sensor-collected images and data to automatically generate digital "safety logs." During patrols, it conducts automated site inspections, using perception, vision systems, and AI to identify common safety issues. Upon detecting problems, it records them and triggers alarms, enabling full-process, round-the-clock site monitoring and early warning.

All-Round Partner

Compared to traditional robots, the AI inspection robot dog offers unique advantages. With exceptional mobility and adaptability, it navigates various terrains and environments, performing complex maneuvers like walking, running, crawling, climbing slopes, and ascending/descending stairs—overcoming the terrain limitations of wheeled robots. It enables multi-angle equipment inspections with no blind spots.

Additionally, as a mobile intelligent edge node, it detects unauthorized non-labor personnel, issuing real-time warnings and expulsions while alerting the backend, effectively serving as a "security guard." By connecting with the command center via the digital management system, it integrates data analysis to visualize on-site information about labor, quality, safety, and materials, achieving transparent, digital project progress management.

Worry-Free Role Model

"Previously, safety inspections required two teams and took three hours. The AI robot dog is much faster, completing patrols in just one hour—reducing manual workload by 80% and improving detection accuracy," explained the Safety Director of the Airbus Tianjin Second Final Assembly Line Project.

The application of the AI inspection robot dog epitomizes the project’s drive toward digital and intelligent transformation in on-site management. Having been recognized as one of Tianjin’s second batch of Smart Construction Pilot Projects, the team will deepen its integration of "Smart Construction Sites" and "Intelligent Construction," leveraging AI large model technologies to accelerate the digital and intelligent upgrade of traditional industries and create new benchmarks for coordinated development of construction industrialization and smart construction.

- The project in Zengcheng, Guangzhou is progressing smoothly.

- Using Router as DHCP Server: How to Configure

- Galaxy Macau Unveils World’s Largest Bentley Flying Spur Mulliner Fleet, Elevating Guest Experiences to New Levels of Luxury

- 2025 Floral Wisper Along the Silk Road:

- 70th main tower of Shenjiang Railway's Modaomen Waterway Bridge successfully top

- Nanfan Silicon Valley" in south China's Hainan Province, February 23. 2022.